Accurately tracking and managing product kits (bundles) at the variation level is one of the most challenging aspects of inventory management.

Add to it the challenge of not showing individual variation pricing of the kit content.

Kirsten Pace, president of LabSmith, faced these exact struggles. To overcome them, she sought assistance from Scott Lewis, who runs a digital marketing agency called Lewis Studios.

Scott implemented the Chained Products for WooCommerce plugin to manage LabSmith’s product kits. This implementation marked a major turnaround, resolving all the challenges LabSmith had encountered.

Let’s explore how.

Meet LabSmith & Lewis Studio

LabSmith has been a pioneer in laboratory equipment for research, product development and OEM applications for over 25 years.

They develop commercial products, primarily applicable in the fields of microfluidics and high-speed experimental control.

Their products are used in various applications, from university teaching labs and innovative startups to global pharmaceutical companies, and can be found in many leading biotechnology products worldwide.

Learn more about their business on:

Coming to Lewis Studios, they specialize in web development, visual storytelling and marketing strategies for small businesses and nonprofits. Know more about their business here.

What struggles did LabSmith face before they discovered Chained Products?

LabSmith faced significant struggles in managing their kit products. They experimented with grouping products, using different product kit plugins, and also consolidating items into a single product. However, each approach had its limitations.

A major challenge was maintaining accurate inventory for the items within their kits, especially since many of these items were also sold separately.

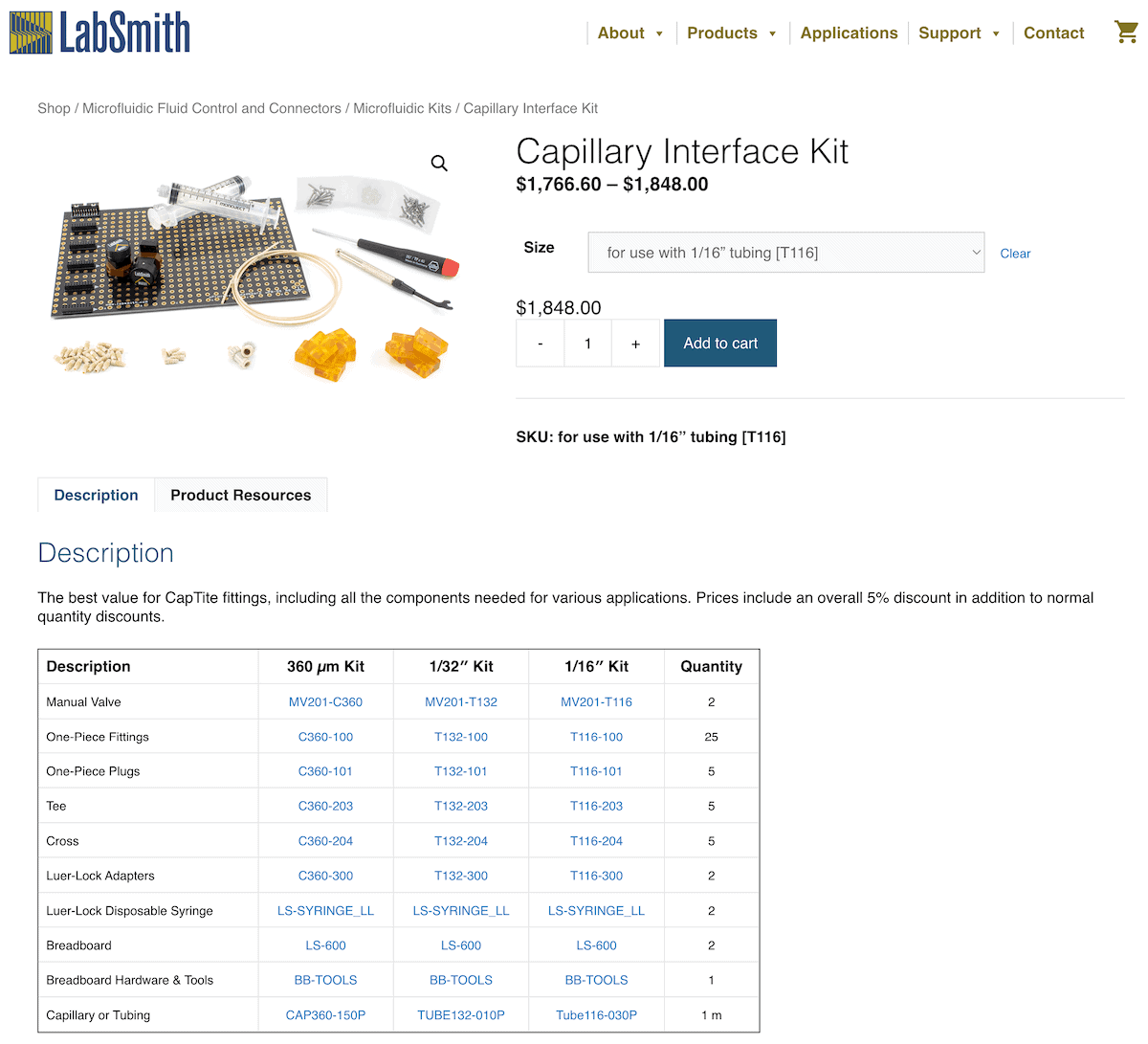

Additionally, they needed to manage the contents of a kit at the variation level, not just at the parent product level, due to the way their kits were configured and sold.

For instance, a kit variation might include several parts compatible with one diameter of tubing in one variation and a different diameter of tubing in another variation.

Managing these variations accurately was crucial. Moreover, they needed the flexibility to avoid pricing each component of a kit individually.

Why did Scott pick Chained Products only?

Chained Products addressed challenges that other plugins couldn’t resolve for LabSmith.

It led to improved product presentation for buyers, streamlined operations for staff, and provided essential controls, such as the ability to avoid pricing kit components individually.

This level of customization was crucial for LabSmith’s needs.

How did Chained Products help manage product kits accurately?

Previously, LabSmith listed kit components in the product description but had to manually keep track of them to pick them up for shipping an order and then update inventory of the component products manually.

Chained Products allowed LabSmith to simplify product and order management by being able to have accurate pick lists for orders based on the products chained to the product ordered.

That’s maintaining accurate inventory levels and streamlining WooCommerce order management.

Using the plugin, LabSmith was also able to clearly show kit contents and the price of the total kit only.

This is especially helpful for educational purchases and new customers/startups. They need a ‘starter kit’ to learn/prototype with before they are ready to order individual parts in higher quantities for their production needs.

Try Chained Products live demo

Why do Kirsten & Scott recommend our Chained Products plugin?

Chained Products met all the requirements for managing kit products. It effectively handled inventory for each component, generated pick lists for order fulfillment, and displayed the total kit price.

Additionally, it encouraged customers to purchase complete kits tailored for specific use scenarios rather than buying individual parts.

This value-driven approach proves more appealing and leads to higher sales compared to selling items individually.